All of the various tools, machinery and devices used in the exploration, drilling, production and maintenance of oil and gas wells are defined as oilfield service equipment. This equipment is essential for the efficient and safe operation of oil fields.

Apart from the operation of oil fields, oilfield service equipment is very important for oilfield workers. The use of equipment and equipment is very important to minimize and prevent oilfield accidents.

Common oilfield service equipment

Wellhead equipment: Wellhead equipment is installed at the surface of an oil or gas well to control pressure and provide a connection point for drilling and production equipment. It includes the wellhead assembly, casing head, tubing head, and various valves and fittings.

Drilling rigs: Drilling rigs are used to create boreholes in the earth’s surface to access oil and gas reservoirs. They can be land-based (onshore) or offshore (floating or fixed platforms). Drilling rigs consist of a derrick, drill string, drill bit, mud system, and power system.

Downhole tools: Downhole tools are used during drilling, completion, and intervention operations to perform specific tasks within the wellbore. Examples include drill bits, drilling motors, measurement-while-drilling (MWD) tools, logging-while-drilling (LWD) tools, and downhole sensors.

Production equipment: Production equipment is used to extract oil and gas from the reservoir and transport it to the surface. This includes artificial lift systems (e.g., rod pumps, electric submersible pumps), separators, heaters, and flow control devices.

Pressure control equipment: Pressure control equipment is essential for maintaining wellbore pressure within safe limits during drilling, completion, and production operations. Examples include blowout preventers (BOPs), choke valves, and kill lines.

Cementing equipment: Cementing equipment is used to mix and pump cement slurry into the wellbore to secure the casing and isolate different zones within the reservoir. This includes cementing units, mixing tanks, and cementing plugs.

Fracturing equipment: Hydraulic fracturing (fracking) is a technique used to stimulate oil and gas production by injecting high-pressure fluid into the reservoir to create fractures. Fracturing equipment includes high-pressure pumps, blenders, and proppant storage and handling systems.

Coiled tubing equipment: Coiled tubing is a continuous, flexible steel pipe used for various well intervention operations, such as wellbore cleanouts, perforating, and acid stimulation. Coiled tubing equipment includes coiled tubing units, injectors, and control systems.

Wireline equipment: Wireline is a cable used to lower tools and sensors into the wellbore for logging, perforating, and other intervention operations. Wireline equipment includes wireline trucks, winches, and logging tools.

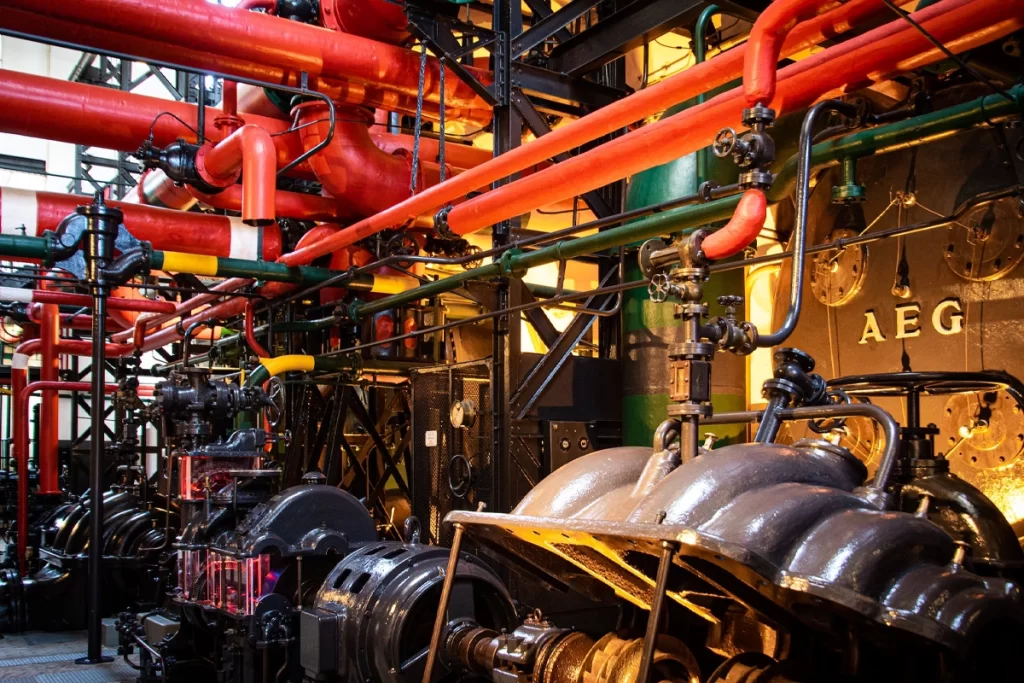

Pipeline and process equipment: This category includes equipment used for the transportation, processing, and storage of oil and gas, such as pipelines, compressors, pumps, and storage tanks.

These are just a few examples of the many types of oilfield service equipment used in the oil and gas industry. The specific equipment required for a particular operation depends on factors such as well location, depth and reservoir characteristics.

The importance of oilfield service equipment

Oilfield service equipment is critical to the oil and gas industry because it enables the exploration, drilling, production and maintenance of oil and gas wells. Without this equipment, it would be impossible to extract oil and gas from the earth’s subsurface and transport it to the surface for processing and distribution.

Some headlines on the importance of equipment:

- Efficiency: Oilfield service equipment is designed to perform specific tasks efficiently and effectively, reducing the time and cost required to complete drilling, completion and production operations. This equipment is often highly automated, reducing the need for manual labor and increasing productivity.

- Safety: Oilfield service equipment is designed with safety in mind, with features such as pressure control systems, emergency shutdown systems and safety valves. These features help prevent accidents and protect workers and the environment.

- Reliability: Oilfield service equipment is built to withstand harsh operating conditions such as high temperatures, high pressures and corrosive environments. This equipment is designed to operate reliably for extended periods of time, reducing downtime and maintenance costs.

To summarize, oilfield service equipment is essential to the oil and gas industry, enabling the efficient and safe exploration, production and transportation of oil and gas. It is designed to be efficient, safe, reliable and innovative, and has a significant economic impact on the global economy.

But above all, safety must always be the oil and gas industry’s top priority. When equipment is used correctly and properly, oilfield accidents and oilfield injuries will be reduced and eliminated.